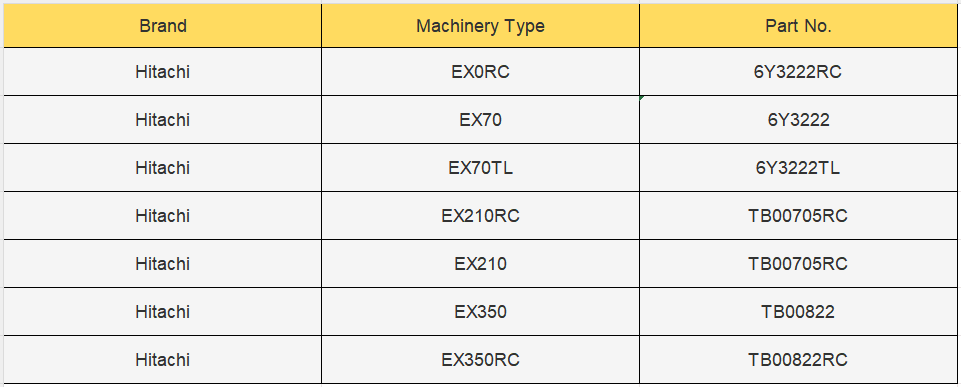

Hitachi Series

All our teeth are using high spec alloy steels to ensure excellent wear characteristics, parts is checked by the

original gages to make sure the fitting is standard and ease of installation wherever possible. Wide range,

quality, service, we are your best choice.

We also have more heavy duty styles

| Material | Alloy steel | Part No. | 1U3202; 1U3302RC; 53103205; 61N6-31310... (Customized styles) |

| Color | Yellow or Customer's Request | Payment | T/T; Paypal; Western Union... |

| Logo | TERA BLADE or Customer's Request | Packing | Plywood case |

| MOQ | 1 pc | Suitable machine | Caterpillar; Komatsu; Volvo; JCB; Hyundai; Doosan... |

| Delivery time | 30-35 days (one container) | Loading Port | Ningbo; Shanghai; Yiwu; Qingdao; Guangzhou... |

How to choose the best bucket tooth type for you?

1. Working environment

Earthwork: For ordinary earthwork, it is recommended to use flat-head earthwork bucket teeth. This bucket tooth design can effectively reduce excavation resistance and save fuel.

Rock excavation: When facing hard rocks, RC rock bucket teeth should be selected, which have better penetration and wear resistance.

Coal seam mining: For coal seam excavation, TL pointed bucket teeth are recommended, which can improve the coal block rate.

2. Bucket tooth material

Forging and casting: Forged bucket teeth are generally more wear-resistant than cast bucket teeth, and their service life can be up to twice that of cast bucket teeth. Although forged bucket teeth are more expensive, they have better long-term economic benefits.

3. Machine model and blade thickness

Confirm the brand and model of the excavator in order to select compatible bucket teeth. At the same time, pay attention to the thickness of the blade. Blades of different thicknesses need to match the corresponding bucket tooth model.

4. Applicable working conditions

Choose the appropriate tooth tip type according to the specific working conditions. For example, for working conditions with medium wear resistance and penetration requirements, you can choose a general-purpose tooth tip; for extreme conditions, you need to choose a reinforced or specially designed tooth tip.

5. Maintenance and replacement

Regularly check the wear of the bucket teeth and replace the severely worn bucket teeth in time. Practice shows that the outer bucket teeth wear 30% faster than the inner ones, so it is recommended to change their positions regularly to even out the wear.

Through the above steps, you can choose the most suitable bucket tooth type according to specific operating requirements and environmental conditions, thereby improving the working efficiency and economy of the excavator.

Custom Bucket Teeth With Easy

At TERA BLADE , We turn complex Into Simple! Follow the following 3 steps to start today!.

Add Your Heading Text Here

Please be as specific as possible about your needs, provide pictures, tell me the brand and model you need and share your ideas.

Add Your Heading Text Here

Please be as specific as possible about your needs, provide pictures, tell me the brand and model you need and share your ideas.

Add Your Heading Text Here

Please be as specific as possible about your needs, provide pictures, tell me the brand and model you need and share your ideas.

We know mining

After 10 years of serving miners exclusively, we understand you, from common challenges to operational priorities

We Work Closely With you

We are on the ground with you , always looking for improvements, solving problems, and supporting you every step of the way to greater productivity

We are Passionate Innovators

Our mission to develop the world's most advanced solutions never stops

FAQ

Q: Are you trading company or manufacturer?

A: We are a professional manufacturer of GET parts located in Shandong, China.

Q: How long is your delivery time?

A: It depends on order quantity. Generally, delivery time will be around 15-30days.

Q: Can you provide samples? is it free or charge?

A: Yes, we could offer free sample but freight collect.

Q: What about Quality Control?

A: We have a perfect QC system for the perfect products. A team who will detect the product

quality and specification piece carefully, monitoring every production process until packing is

complete, to ensure product safety into container.