Larger Capacity, Better Price.

Annual production up to 30,000 tons & lower wholesale price.

Lower MOQ, More Flexibility.

Save you more and generate higher profitability with 200KG MOQ

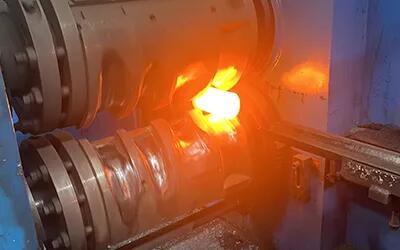

Forging process

Compared with casting, forging is more wear-resistant and can save replacement costs

After-sales service guarantee

Provide a quick response mechanism to handle customer feedback in a timely manner

1. Mold processing

5. Pre-forging molding

9. Billet forming

13. Shot blasting

2. Material cutting

6. Final forging(precision forging)

10. Mesh belt furnace heat treatment

14. Anti-corrosive dip-painting

3. Medium frequency furnace heating

7. Remove burrs

11. Quality inspection

15. Packing and shipping

4. Roll forging machine billet making

8. Punching and shaping

12. After passing the inspection polishing

16.Shipping

Our Happy Clients From 30+ Countries

“We have been using traditional cast bucket teeth before, but frequent breakage and wear gave us headaches. Since we used the forged bucket teeth from this factory, the situation has completely changed! The bucket teeth are not only wear-resistant, but also perform well in hard rock environments. The service life of a single bucket tooth has increased by more than 30%, greatly reducing the frequency of replacement, saving time and maintenance costs.”

“Our construction site operations require penetrating hard soil and rocks, but ordinary bucket teeth are often severely worn and lack penetration. This forged bucket tooth uses high-strength steel and has very strong penetration, which has improved the excavation efficiency by at least 20%! We are very satisfied with the faster construction schedule and significantly reduced equipment downtime.”

"We mainly excavate concrete and gravel at our project site. In the past, the bucket teeth we used often broke, which caused us a lot of trouble. However, the forged bucket teeth of this factory performed very well, with high hardness and strong impact resistance, and have not broken so far. The quality is stable and reliable, and it is a partner we trust."

"We purchased forged bucket teeth for government projects. Although the unit price is slightly higher, in actual use, the service life is longer, and the cost performance is very high in the long run! The after-sales service provided by the factory is also very considerate, with quick response and timely problem solving. It really saves customers worry and effort!"

"Our equipment requires bucket teeth of special sizes, and many suppliers we have previously found could not meet our requirements. This factory provided a customized solution and quickly produced forged bucket teeth that met our needs. The quality was excellent and the installation was precise, which solved our problems. It is a great pleasure to cooperate with you!"

We are an integrated industry and trade enterprise with our factory located in Shandong and our sales department located in the center of Qingdao.

Give us correct machine/model number/part numbers on the parts itself. Or measure the parts give us dimension or drawing.

It depends on what you are buying. Normally, we don't have MOQ request.

If don't stock in factory : 20 days . If there are any parts in stock , our delivery time is only 7-10 days.

We have a perfect QC system for the perfect products. A team who will detect the product quality and specification piece carefully, monitoring every production process until packing is complete, to ensure product safety into container.

For forged bucket teeth we can offer free sample, but the clients need bear the freight.